Product Designer

I love to design novel products. I start from the ground up, combining research, 3D modeling, prototyping, wiring and iterative testing to create a working solution.

Mechanical Engineer

I received my bachelors degree in Mechanical Engineering in 2024. I apply my understanding of manufacturing processes and engineering principles to develop solutions with a fundamental approach.

Programmer

I learn through hands-on experience, working on dozens of programming projects across software, firmware, and AI/ML. Many of my projects introduced novel solutions, tackling challenges in automation, embedded systems, and industrial applications.

Origin

I designed the components with manufacturability in mind, ensuring that plastic parts were optimized for injection molding and metal parts were engineered for stamping.

Additionally, I collaborated with multiple suppliers specializing in load cells, RFID, injection molding, LCD screens, custom PCBs and hinges. This involved assessing the suppliers capabilities, providing design specifications, and working closely with them to guarantee that each component met our functional, quality, and production requirements.

Link

The Link was a progression beyond hardware into a more versatile product. This product was purely software, which took the same concepts as the Origin and turned it into a IOS and Android app.

Hub

The Hub is a simple device which relays weight data from a scale into the CloudBox system to allow users to easily automate cycle counts.

I designed this device with a powder coated aluminum plate, CNC’ed and bent into a shape which could fit around the 3D printed bottom housing.

Since this device was low volume, I chose to use 3D printing and CNC as a way to reduce initial tooling costs.

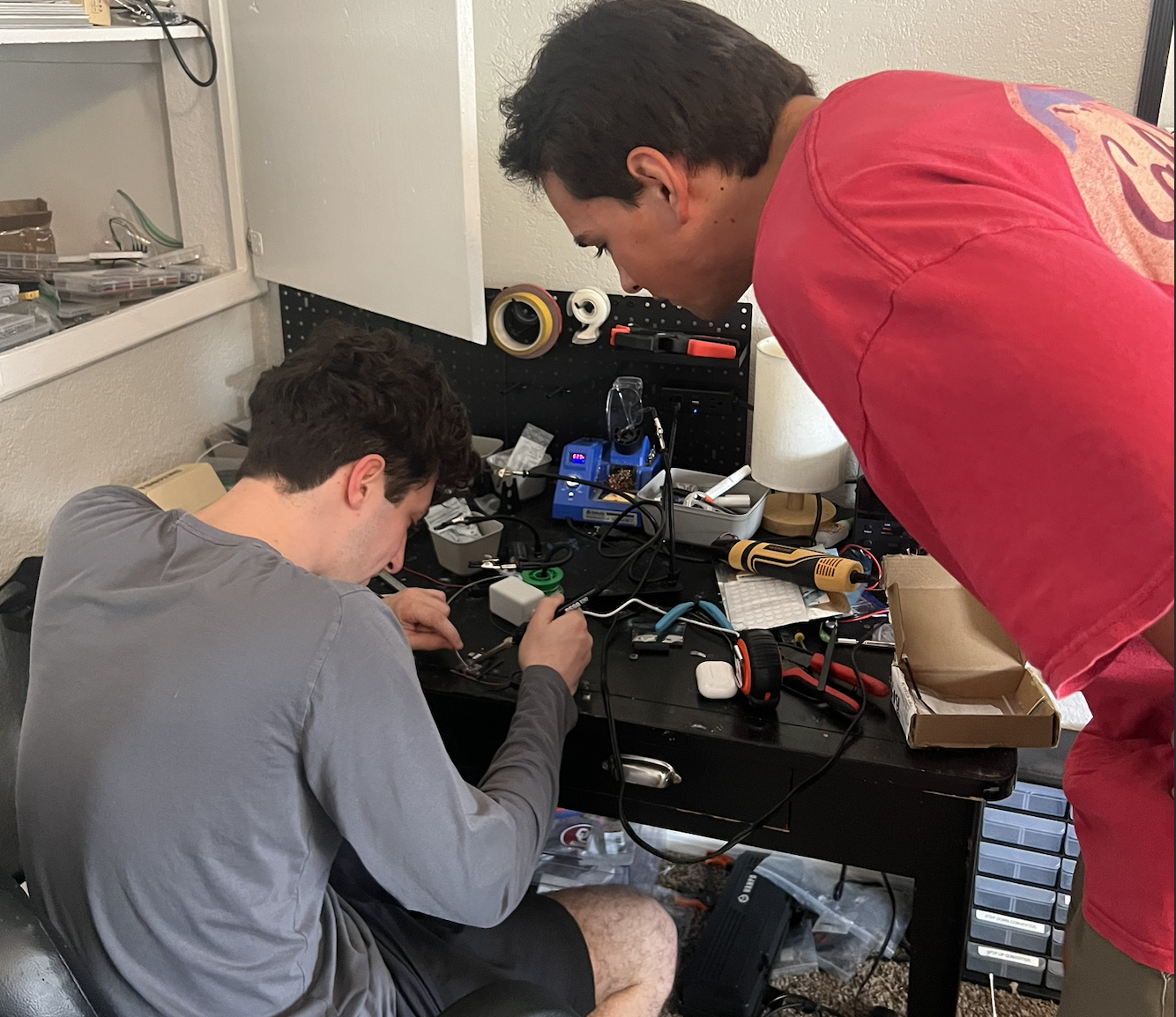

Ascent Rocketry

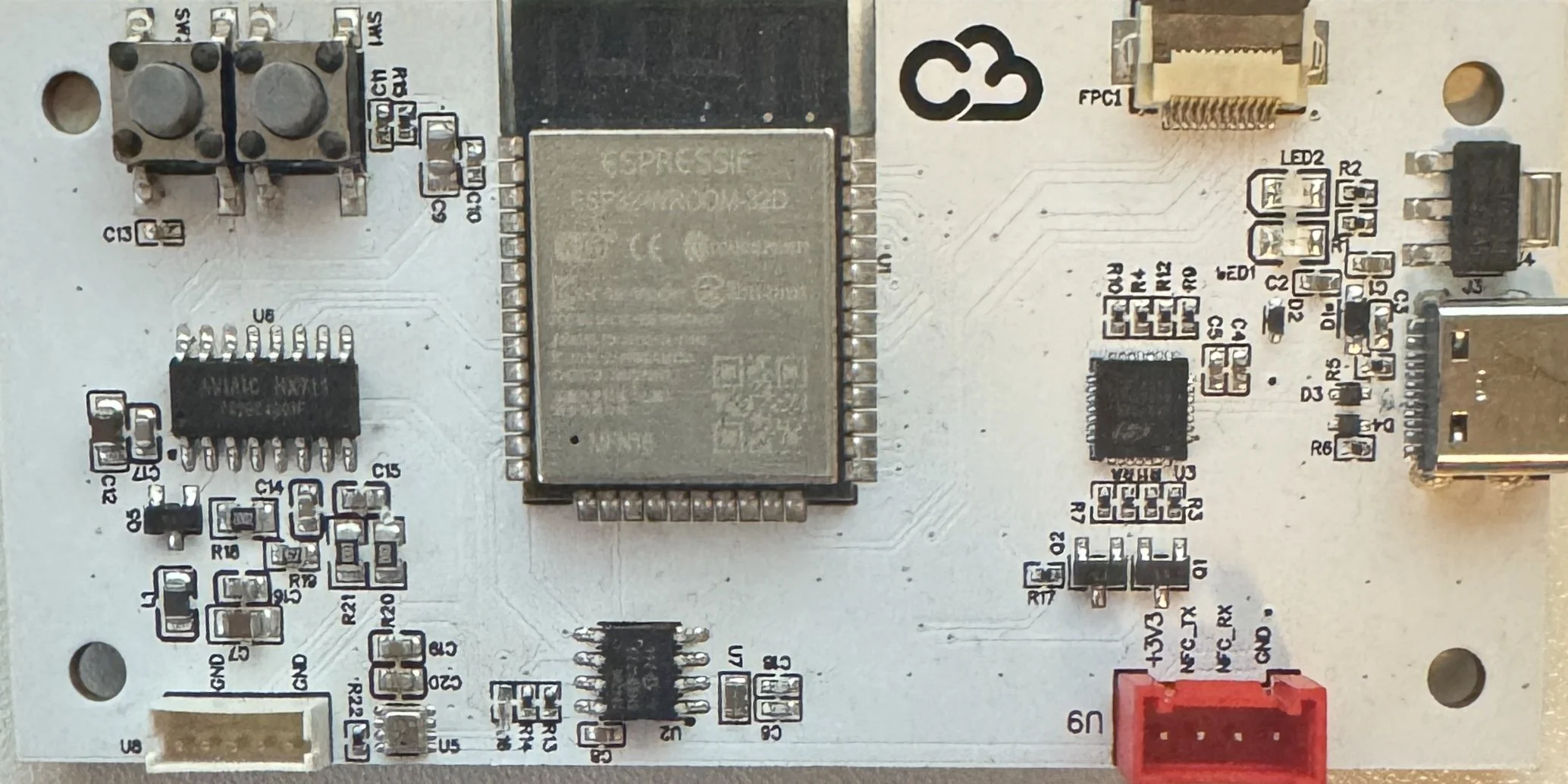

I worked alongside another engineer in the development of an end-to-end control system for igniting a rocket by controlling a spark and opening multiple solenoid valves for oxygen and fuel (kerosene). The system utilizes an ESP32, which connects to a phone via the ESP32s built-in WiFi. A mobile app guides the user through initiation and confirmation steps, significantly improving safety by allowing the operator to remain at a safe distance in the event of an unintended explosion.

SENSE-Products

LockSENSE

There have been many times when I walk to my car and forget whether I locked the door. This device solves that problem by using an accelerometer to detect when a door has been locked. Once detected, a light turns on, allowing the user to quickly check and confirm that the door is secured later in the day.

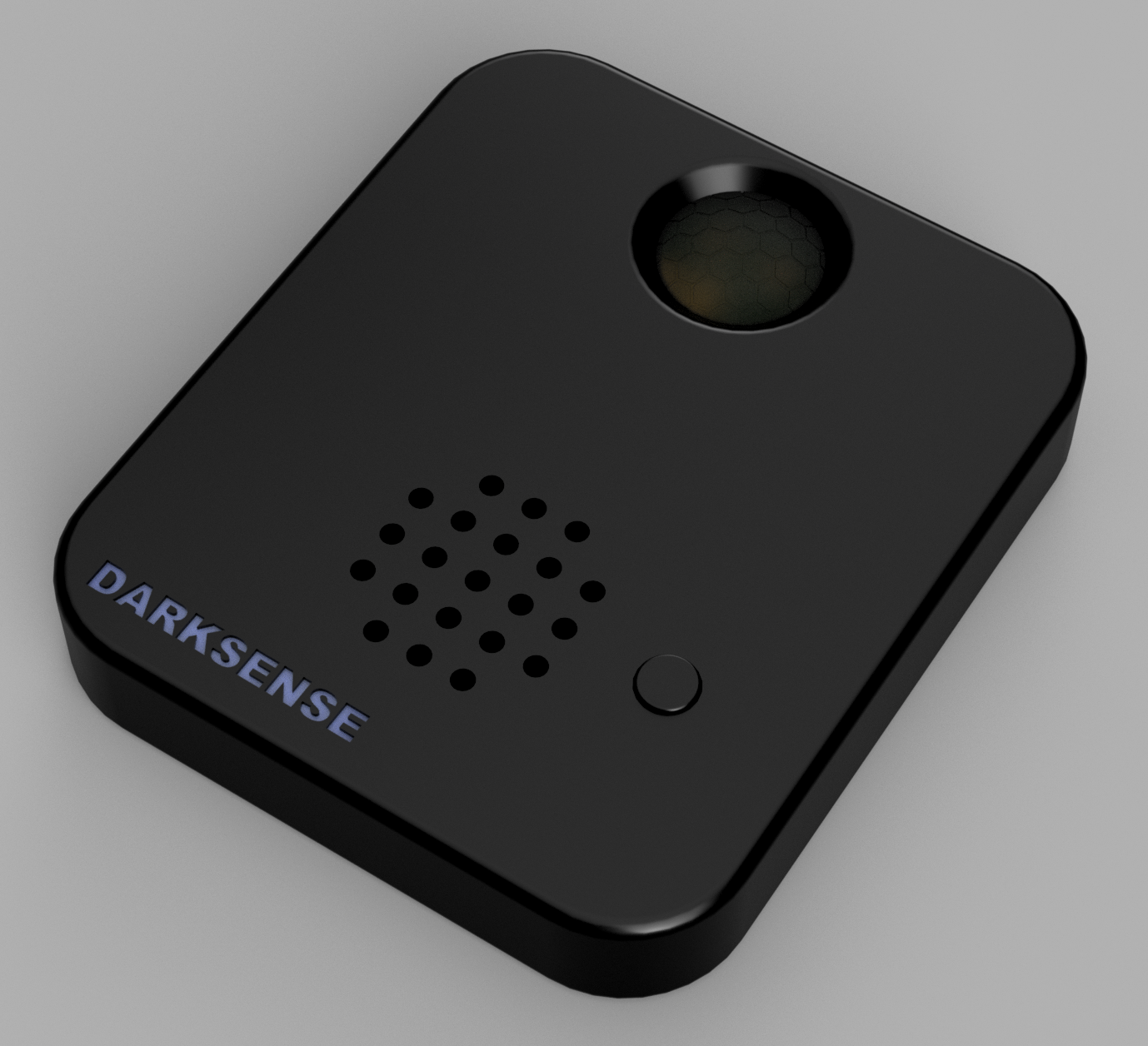

DarkSENSE

DarkSENSE is a small device that plays sounds like growls or cricket chirps whenever the lights go out. It uses a photoresistor to detect darkness and randomly triggers the sound you set. It was a fun consumer device project to work on.

I designed custom jigs, fixtures, and specialized tools to speed up manufacturing and assembly processes, improving efficiency and consistency.

I integrated multiple systems using Ignition, Node-RED, Python scripts, and PLCs, and relays.

These systems directed and controlled AMR operations, doors opening, inspection cameras, and indication lights.

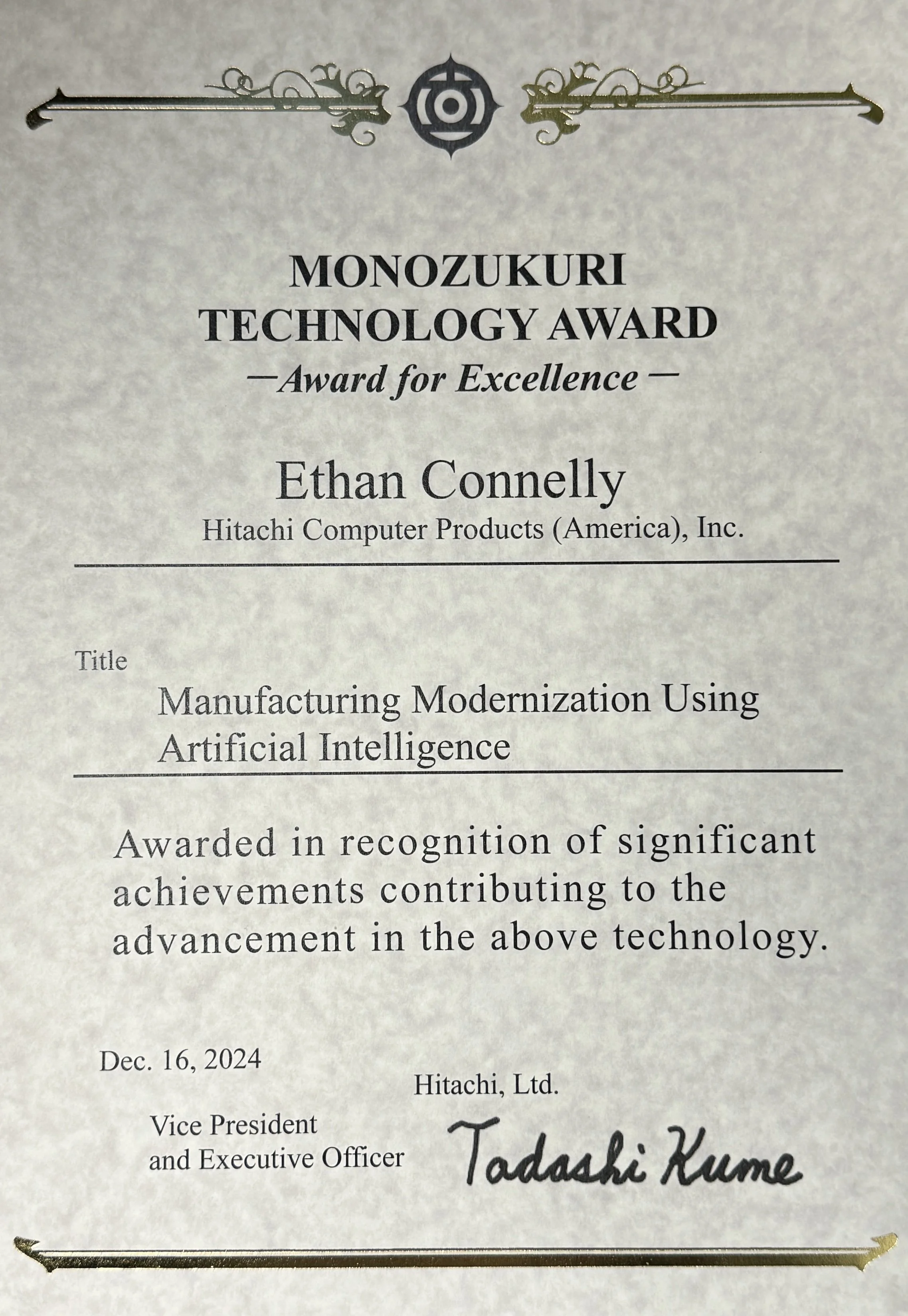

I developed a system using Ultralytics YOLO and OpenCV to guide operators in correctly installing boards when assembling storage racks. This eliminated installation errors, significantly improving quality.

The system featured an AI Training Interface and Configuration pages, enabling users to upload images, train models, and deploy them for object detection, providing real-time feedback to operators. The project earned the company several awards.

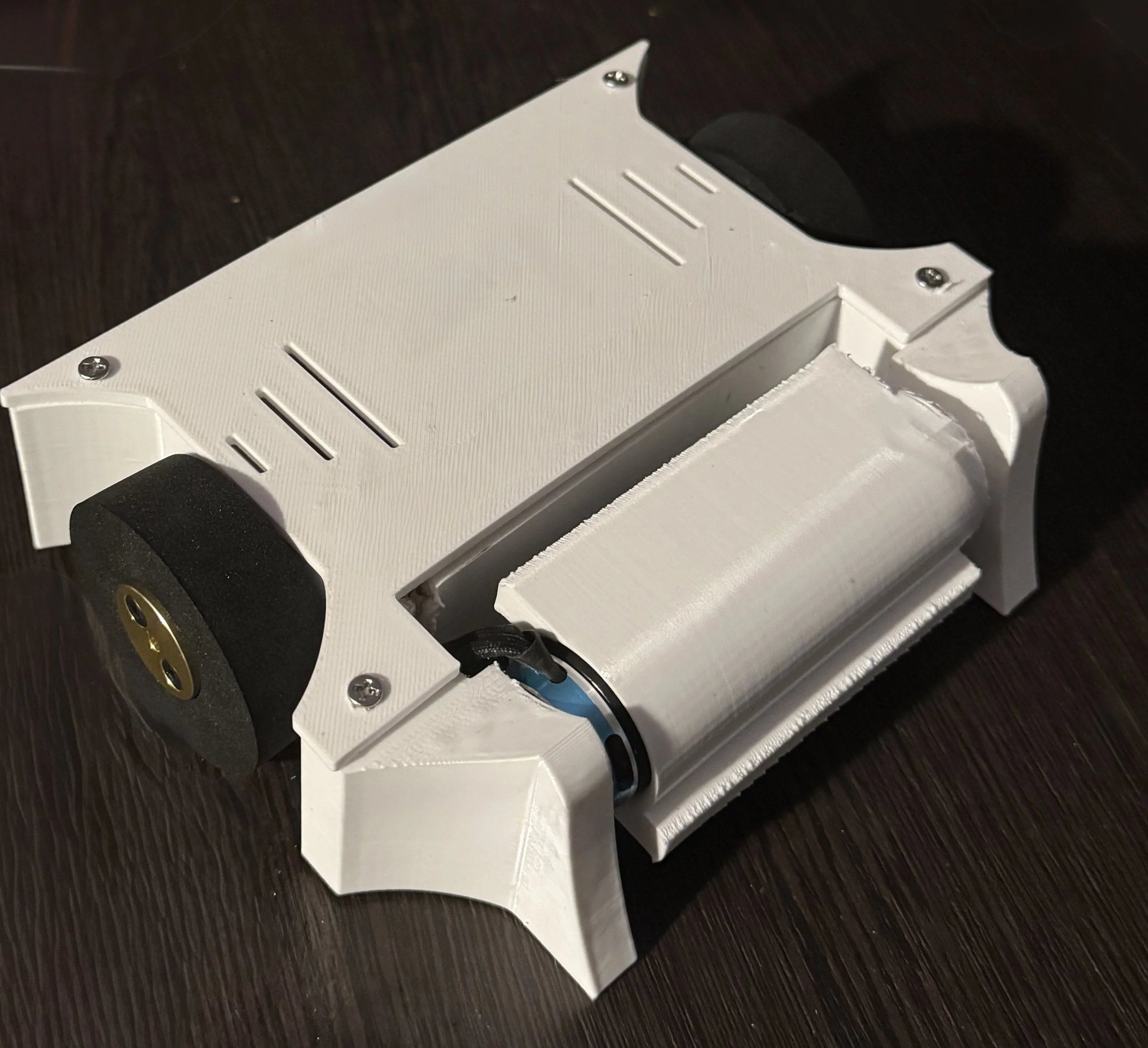

Robotics

I designed, 3D-printed, and assembled multiple robots for arena battles. This process included selecting components, integrating them with custom-designed parts, and connecting them to a controller for combat.

I worked with team members to coordinate events, ensuring robot battles were safe. Additionally, managed and organized events to guarantee smooth operations.

While I was Vice-President, Crimson Robotics held several tournaments each featuring near 100 robots from many Universities and States.